”Fusube is a rare technique that remains in Japan. I would like to take over the tradition and make it known to many people. “

-The Fusube technique-

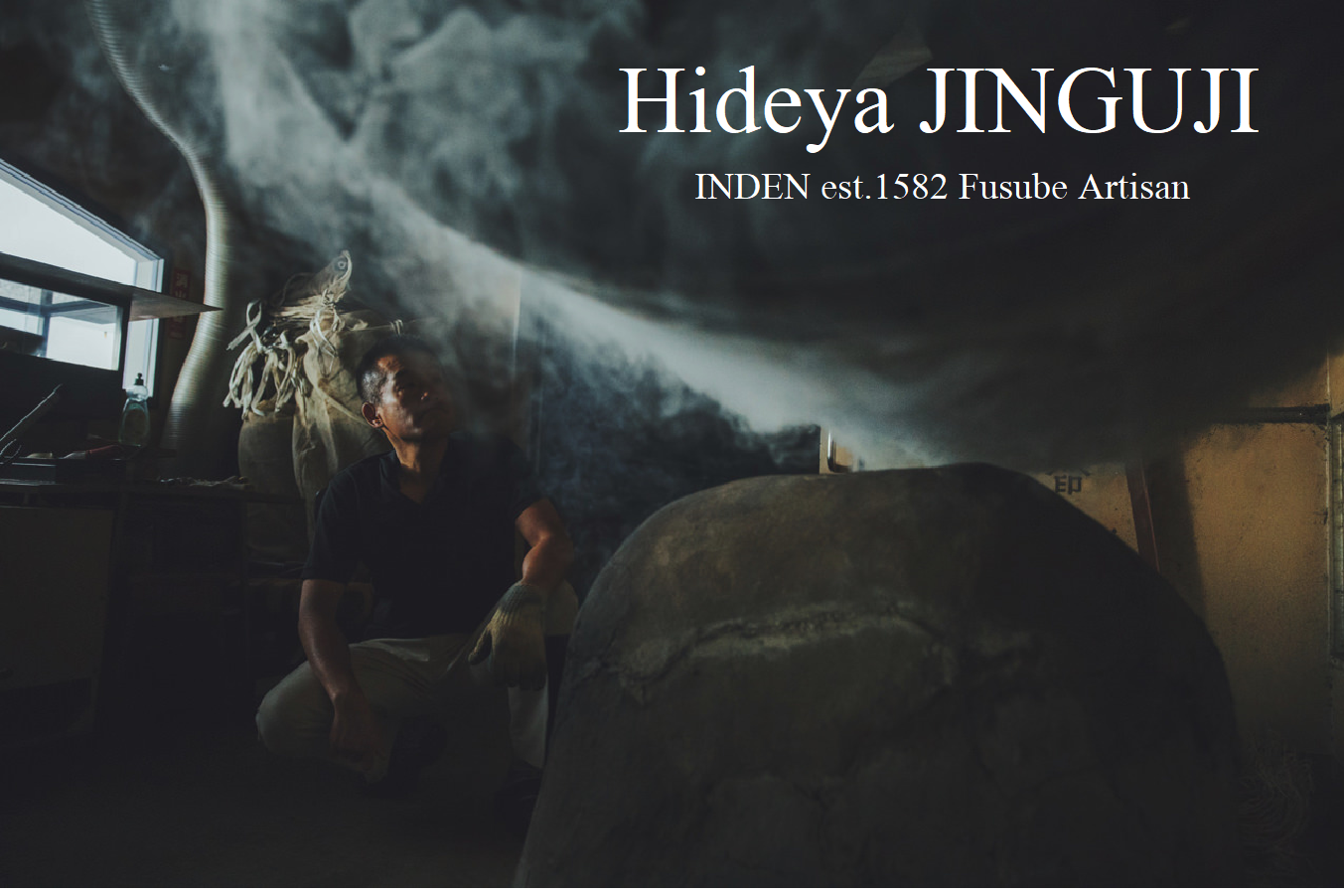

This is a technique in which white leather is wrappwd on a cylinder called Taiko, and the leather is dyed dark brown by burning straw and exposing it to the smoke. The color can be changed by which material, how long, and how many times the straw is burned. Various patterns can also be created by using threads to create stripes, or by using stencils and glue. This Fusube technique is said to be the root of Inden. We interviewed Mr. Jinguji, the only Inden Fusube craftsman who has taken over the unchanged technique and continues to preserve the tradition.

What inspired you to become a Fusube craftsman?

Since Mr. Jinguji was a child, he enjoyed building plastic models. He was good with his hands, so he wanted to have a job that involved making products. Before working at Inden-ya, he had another job related to machine manufacturing. While working, he spent his days feeling that something was missing. One day at the age of 21, he found a job offer for a traditional craft at a local Inden-ya and applied for it. Now he is devoted to Inden.

Working at Inden and tradition

After joining Inden, Jinguji's training began with lacquering in the lacquer department. After about five years of experience in lacquering, he began learning the current fusube technique. Since the timing was right for a generational change, he began to take over the baton of fusube techniques while learning both fusube techniques and lacquer painting. His first fusube work was a crossed pattern with two diagonal lines crossing equally on both sides. From there, he has been mastering the fusube technique for more than 20 years.

Secret Methods of Family Tradition

“Japanese people skillfully use only straw smoke for coloring.”The missionary Luis Frois, who is known to have had an audience with Nobunaga, wrote of his amazement at this technique in his book.

400 years of history

Inden technology has continued for 400 years. In the bestseller "Tokaido chu hizakurige" from the Edo period, a purse made of this technique is mentioned. In the long history of the Inden technique, the craftsman Jinguji is committed to learning from his predecessors and passing it on to future generations. Of course, the history is important, but he also places importance on the present. There is no manual for Inden techniques. He has found his own way to preserve the technique that has been used for 400 years, and continues to produce the same quality. He continues to train himself and learn with his body. He says that repeated practice is the key to success.

The difficulty of fusube

When we asked him about the difficulties in the fusube process, he replied that it is difficult to describe in words, as he has been doing it for 20 years and is already familiar with the process. However, if he had to say, he would say that it is the "humidity," which he cannot adjust himself. In the fusube process, he adjusts the amount of straw, timing of rotation, and time of smoking according to the season, temperature, and humidity. He follows his own senses in the dyeing process. In order to get a sense of this, he practiced over and over again in the beginning. He was able to grasp the sense of craftsmanship when there were no more failures.

The way the color is dyed varies from deer to deer. Since he is working with living creatures, the adjustment of the color depends on the skill of the craftsman. The quality of the deer also changes depending on the deer's origin, and each deer has its own individuality, so it is necessary to carefully observe the individuality of each deer.

Typical patterns of fusube include three stripes, crossed stripes, dragonfly pattern, Shohei pattern, Goshoguruma pattern, and Shobu pattern. The Shobu pattern is said to be the most delicate to make because it is the most prone to stains and scratches. Interestingly, simple patterns are more difficult to make because they require more adjustments.

Furthermore, the smoke from fusube is hot, and it can take up to three days to dye deerskin, which is sensitive to high heat. The smoke is not given all at once to maintain the softness of the deerskin. While checking the coloring, it takes 2 or 3 days to dye the leather beautifully. Only a trained craftsman can feel the difference.

Fusube Craftsman

at INDEN

The only technique in Japan that only skilled craftsmen can make full use of. This is the root of Inden-ya, which is now taken over only by the craftsman Jinguji.

The charm of fusube that Jinguji craftsman thinks

Jinguji is the only craftsman who currently inherits the Fusube technique. He says that the charm of the fusube technique is the feel of the deerskin leather. The soft feel is unique to fusube, and you should definitely experience it for yourself.

Inheritance

The fusube technique is one that has been handed down from generation to generation only to the patriarch, Yushichi.

Moments that made him happy in his 20 years as a craftsman and challenges for the future

He says that the most rewarding moment for him as a craftsman is when he sees people using inden on the street. Fusube is expensive and few people use it in their daily lives, so it is difficult to find people using it. However, he has seen someone carrying a fusube wallet once or twice. That was the most impressive moment for a craftsman Jinguji.In Yamanashi Prefecture, there is no one who does not know Inden. However, Jinguji's future task is to promote Inden, particularly Fusube, so that people all over Japan and the world will know and use it.

Craftsman Jinguji’s Best Yamanashi Spot

He often goes to Lake Motosu to windsurf on his days off. Lake Motosu has a lot of nature and good wind. It is highly recommended for windsurfing enthusiasts and those who want to avoid crowds and feel nature. Incidentally, the reverse side of the 1,000 yen bill depicts Mt. Fuji and Lake Motosu. As for food, Yamanashi Prefecture is famous for its horse meat sashimi. It is a very tasty appetizer that can be enjoyed with alcoholic drinks, so when you come to Yamanashi, you should try it.